简介

Eta100 Ultra 光学麦克风结合声光传感器技术,通过单个传感器头覆盖从10 Hz到1MHz的声频带宽。Eta100 Ultra光学麦克风设计为声场表征传感器,可承受高达180 dB (A) SPL的极高声压级。它非常适合于超声探测中的超声波焊接以及USP激光无损检测应用。

Eta250 Ultra 光学麦克风通过单个传感器头覆盖10 Hz至1 MHz的声频带宽,专为过程监控而设计。作为超声测量和超声波监控传感器,它适用于对自身噪声要求较低的应用。

Eta450 Ultra 光学麦克风是一种非接触激光超声检测传感器,可用于对多种材料进行无损检测(NDT)。该传感器的频率带宽范围为50 kHz至2 MHz,适合与宽带激光超声波激励结合使用。它紧凑的尺寸和非接触特性使其成为对复合材料、点焊和粘合接头进行激光无损检测的理想选择。

Eta600 Ultra 光学麦克风代表了传感器技术的新进展。其频率带宽范围为50 kHz至4 MHz,专为空气耦合超声测量而设计,具有高灵敏度,是需要高分辨率的超声波测试应用的理想选择,包括航空航天工业中使用的半导体元件和复合材料的无损检测(NDT)。

特征

- 无膜光学麦克风

- 频率范围:

- 10 Hz-1 MHz(声学和超声波)

- 50 kHz–2 MHz(Eta450 Ultra)

- 50 kHz–4 MHz(Eta600 Ultra)

- 动态范围:

- 80-180 dB(A)SPL (Eta100 Ultra)

- 50-150 dB(A)SPL (Eta250 Ultra)

- 100 dB(Eta450 Ultra)

- 95 dB(Eta600 Ultra)

应用

- 度量学

- 非破坏性测试

- 过程控制

技术参数

| Eta100 Ultra | Eta250 Ultra | Eta450 Ultra | Eta600 Ultra | |

| 传感器类型 | 无膜,光学 | |||

| 频率范围 | 10Hz – 1MHz | 10Hz – 1MHz | 50kHz – 2MHz | 50 kHz – 4 MHz |

| 动态范围 | 100dB | 100dB | 100dB | 95dB |

| 自噪声 | 1.5 mPa(BW:1Hz,@ 1kHz测量) | 50μPa(BW:1Hz,@ 1kHz测量) | 5μPa(BW:1Hz,@ 500kHz测量) | 3.5μPa(BW:1Hz,@ 500kHz测量) |

| 自噪声,全带宽 | 1.5 Pa | 50mPa | 10mPa | 10mPa |

| 最大声压THD <3% | 1.2 kPa | 400 Pa | 40 Pa | 20Pa |

| 最大声压级THD<3% | 176dB rel.20μPa | 146dB rel.20μPa | 126dB rel.20μPa | 120dB rel.20μPa |

| 损伤阈值 | > 194dB rel. 20μPa | |||

| 灵敏度 | 0.35mV / Pa @ 1kHz(0dB增益,50欧姆) | 10mV / Pa @ 1kHz(0dB增益,50欧姆) | 100mV / Pa @ 1kHz(0dB增益,50欧姆) | 200mV / Pa @ 1kHz(0dB增益,50欧姆) |

| 极化模式 | 全向 | |||

| 声场优化 | 自由场和压力场 | |||

| 与活塞校音器或校准器兼容 | Yes, 标准校准器(带适配器) | |||

| 通用参数 | ||||

| 输出电压 | ±15V(高阻抗),±7.5V(50欧姆) | |||

| 输出连接器 | BNC | |||

| 传感器尺寸 | 直径:5mm; 长度:38mm | 直径:5mm; 长度:38mm | 直径:8.8mm; 长度:35mm | 9 x 5 x 35mm |

| 传感器重量 | 约10g | |||

| 光纤长度 | 5米(根据要求可选) | |||

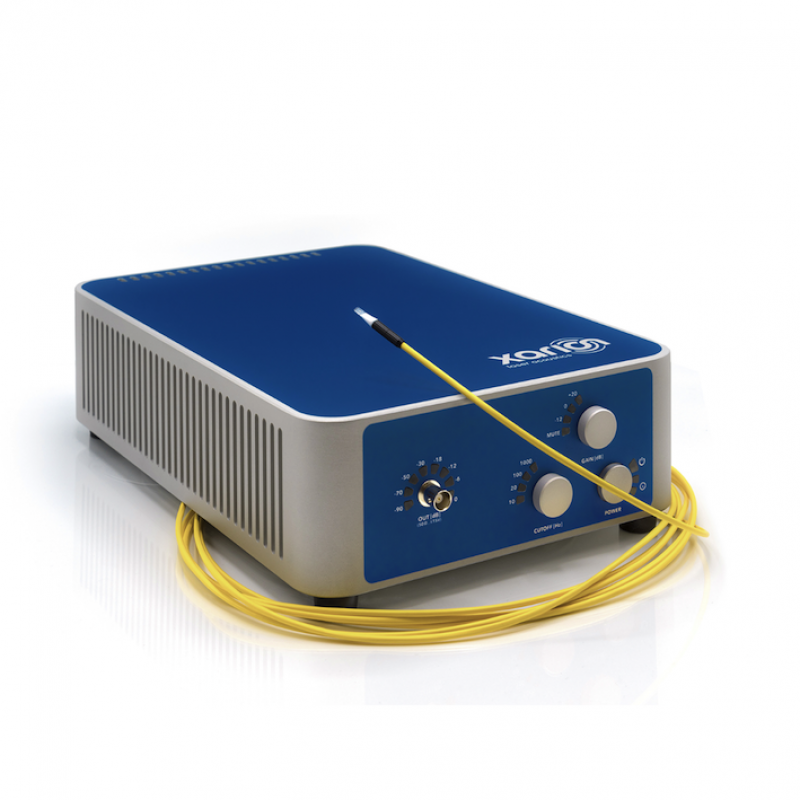

| 控制器尺寸 | 220 x 334 x 93 mm | |||

| 控制器重量 | 8kg | |||

| 电源 | 120/230V±5%; 50 / 60Hz | |||

| 功耗 | <50W | |||

| 环境要求 | ||||

| 存储温度 | -20°C to 80°C | -20°C to 80°C | -20°C to 80°C | -20°C to 80°C |

| 传感器的工作温度 | -20°C to 100°C | -20°C to 100°C | -20°C to 100°C | -20°C to 100°C |

| 控制器的工作温度 | 15°C to 30°C | 0°C to 50°C | 0°C to 50°C | 0°C to 50°C |

| 湿度 | 无结露 | |||

相关文章

Eta100 Ultra

- Characterization of polymer-based piezoelectric micromachined ultrasound transducers for short-range gesture recognition applications

- Development of an innovative measurement system for audible noise monitoring of overhead lines

- Optical microphone hears ultrasound

Eta250 Ultra

- Acoustic Process Control for Laser Material Processing

- Air-Coupled Ultrasonic Inspection of Fiber-Reinforced Plates Using an Optical Microphone

- Akustische Überwachung für die Lasermaterialbearbeitung (German)

- Inline Process Monitoring of Hairpin Welding Using Optical and Acoustic Quality Metrics

- Online cracking detection by means of optical techniques in laser‐cladding process

- Ultrasound inspection of spot-welded joints

Eta450 Ultra

- Air-Coupled Ultrasonic Inspection of Fiber-Reinforced Plates Using an Optical Microphone

- Impact damage assessment in biocomposites by micro-CT and innovative air-coupled detection of laser-generated ultrasound

- Material characterization via contact-free detection of surface waves using an optical microphone

- Ultrasound inspection of spot-welded joints

- Laser-Excited Acoustics for Contact-Free Inspection of Aeropace Composites

- Thickness measurement via local ultrasonic resonance spectroscopy

Eta600 Ultra

- Air-Coupled Ultrasonic Inspection of Fiber-Reinforced Plates Using an Optical Microphone

- Impact damage assessment in biocomposites by micro-CT and innovative air-coupled detection of laser-generated ultrasound

- Material characterization via contact-free detection of surface waves using an optical microphone

- Ultrasound inspection of spot-welded joints

- Acoustic Process Control for Laser Material Processing

- Akustische Überwachung für die Lasermaterialbearbeitung (German)

- Inline Process Monitoring of Hairpin Welding Using Optical and Acoustic Quality Metrics

- Online cracking detection by means of optical techniques in laser‐cladding process